Categories

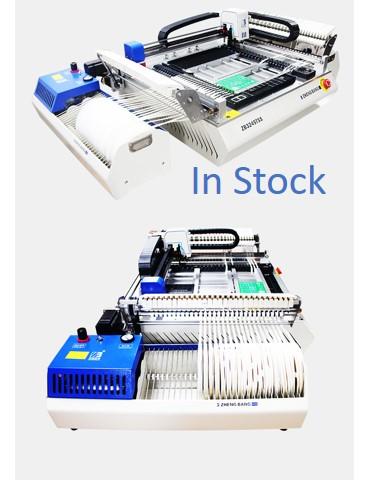

SMT pick and place machine ZB3245TSS

- Model : ZB3245TSS

- Add To Inquiry

- Have a question?

- Share:

Details

54 Feeder Location Automatic VisualPick and Place Machine ZB3245TSS SMT pick and place machine meet the design concept ofmulti-material and multi-variety components, which is suitablefor small and medium-sized batch production, experimentaldevelopment, school teaching and other purposes.

Characteristic:

1.Making the position,speed and moment of forceclosed cycle control and solve the stepper servomotor out of step problems.Eventually achieved High precision positioningand smooth low speed operation requirements.

2.Double Mark point identification and positioningfunction automatically corrects the deviationcaused by PCB irregularity and position deviation.

supportmaximum 320*450mm PCBSuitable for most PCB mounting.

3.Support 54 bit automatic stripping film feederTUBE vibration feeder IC trayMeet diverse needs.

4.High precision identification camera to improvelarge IC identification and placement accuracyCorrection the material offset.

5.Maximum 5500pcs/h mountingAchieve high speed mounting requirements.

6.Both XY axis adopts Taiwan HIWIN linearguide rail, more stable and more accurate.

7.The fast double camera recognition system isadopted for different package chips to improvethe efficiency of resistance and capacitancechip recognition.

8.Japan UNITTA 15mm width beltWith much good wear resistance and aging resistanceNot easy to deform and stretch, makes the machinehave a high precision.

9.Independent research and development ofpneumatic feeding systemcomparing with other similar products on themarket, it perfectly improved the belt problemsuch as easy to break and and so on.

10.Universal SMT NozzleMeet the different packaging requirements.

11.Embedded industrial PC, quality muchmore stable and reliable.

Characteristic:

1.Making the position,speed and moment of forceclosed cycle control and solve the stepper servomotor out of step problems.Eventually achieved High precision positioningand smooth low speed operation requirements.

2.Double Mark point identification and positioningfunction automatically corrects the deviationcaused by PCB irregularity and position deviation.

supportmaximum 320*450mm PCBSuitable for most PCB mounting.

3.Support 54 bit automatic stripping film feederTUBE vibration feeder IC trayMeet diverse needs.

4.High precision identification camera to improvelarge IC identification and placement accuracyCorrection the material offset.

5.Maximum 5500pcs/h mountingAchieve high speed mounting requirements.

6.Both XY axis adopts Taiwan HIWIN linearguide rail, more stable and more accurate.

7.The fast double camera recognition system isadopted for different package chips to improvethe efficiency of resistance and capacitancechip recognition.

8.Japan UNITTA 15mm width beltWith much good wear resistance and aging resistanceNot easy to deform and stretch, makes the machinehave a high precision.

9.Independent research and development ofpneumatic feeding systemcomparing with other similar products on themarket, it perfectly improved the belt problemsuch as easy to break and and so on.

10.Universal SMT NozzleMeet the different packaging requirements.

11.Embedded industrial PC, quality muchmore stable and reliable.

12.Patented Bilateral Feed System.Solve most of the nylon wheel on the marketfeeding difficult, return trouble, stripping is notallowed, easy to break and other problems.

Parameter List

| System | Project | Content |

| MountingSystem | Mounting Numbers | 2PCS |

| Mounting Precision | 0.025mm | |

| Mounding Angle | 0~ 360° | |

| Theoretical Speed | 8000 PCS/h | |

| Normal Mounting | 5500 PCS/h | |

| Visual Mounting | 4500 PCS/h | |

| Suction Nozzle Type | Juki Series Nozzle | |

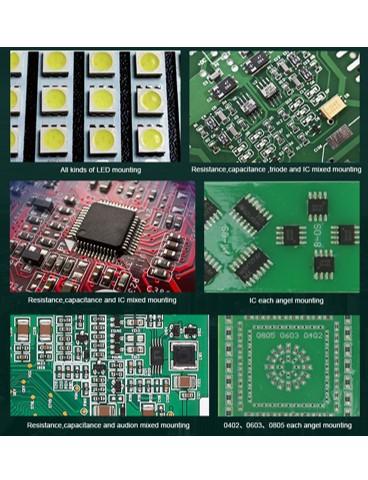

| Applicable Element | RC (0402、0603、0805、1206 .etc) | |

| LED Lamp Beads (0603、0805、3014、5050.etc) | ||

| Chip (SOT、SOP、QFN、BGA.etc) | ||

| PCB | PCB Minimal Size | 10x10 mm |

| PCB Maximum Size (No Tray | 320x450 mm | |

| PCB Maximum Size (With Tray) | 320x220 mm | |

| PCB Thickness | ≤2mm | |

| PCB Warping Allowable Value | <1mm | |

| Feeder Tank | 8mm | 40 PCS |

| 12mm | 8 PCS | |

| 16mm | 4 PCS | |

| 24mm | 2 PCS | |

| Preposition IC Material Level | 10 PCS | |

| Postposition IC Tray | 1 PCS | |

| Tubular Materlals Heeder | Five tubular materials feeder one(optional) | |

| X/Y/Z Axis | X/Y Axis Moving Range | 450x530 mm |

| Z axis Moving Range | 19 mm | |

| Z axis Rotation Angle | 0~ 360° | |

| Visual System | Visual System | Researching and development independently |

| A Visual Camera | CCD High-definition camera | |

| Numbers of Visual | 4 PCS | |

| Recognition Capability | MAX.20*20mm | |

| Control System | PC System | Microsoft WIN7 |

| Operational Software | Researching and development independently | |

| Compatible File Format | CSV、TXT.format | |

| Program Method | Support online and offline ways | |

| Basic Parameter | Air Pressure | 0.4 Mpa (the built-in pump) |

| Vacuity Degree | -66kpa | |

| Power | 150 W | |

| Power Supply | AC220V±10% 50Hz | |

| Main Engine Outline Size | L 990 x W 730 x H 385 mm | |

| 1# Materials Feeder Outline Size | L 235 * W 700 * H 245 mm | |

| 2# Materials Feeder Outline Size | L 235 * W 485 * H 245 mm | |

| Weight | 85kg |

Related Products

- SMT pick and place machine ZB4050LY/LS

- Add To Inquiry

- SMT pick and place machine ZB3245TSS

- Add To Inquiry

Subscribe for our latest Updates

Stay up to date with the latest news, announcement and articles.

- Contact Us

- Build 7, No. 500, Huapu Rd., Qingpu Dist., Shanghai, China

- +86-159-2111-5263

- sales@jillionsupply.com

- +86-159-2111-5263

- +86-159-2111-5263

- jillionsupply

CopyRight © 2002-2025 JILLIONSUPPLY.com

My Cart ( 0 )

- sales@jillionsupply.com

- +86-159-2111-5262

- +86-159-2111-5263

- +86-159-2111-5264

EN

EN RU

RU